- Company Name:

NINGBO CHAP MEH SANDT DEVELOPMENT CO.,LTD - Contact Person: Lydia Yang

- Tel: 86-574-83086181

15867874911 - Fax: 86-574-83086082

- Email: info@chap-china.com

- Address: Lixie village,hengxi town,Yinzhou District,Ningbo,Zhejiang,China

- WebSite: http://www.chapmachinery.com/ http://www.chap-machinery.com

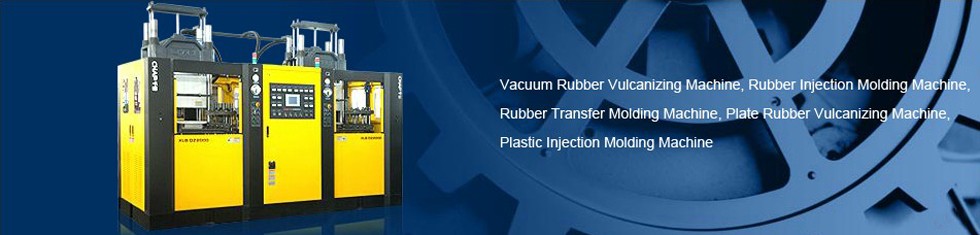

The transfer type molding machine for rubber(semiautomatic rubber injection molding machine) is an advanced rubber pressure molding equipment,it is suitable for producing rubber model products with metallic insert, complex shape, big cross-section and thick-wall., these products' process is complex and more difficult to form. Among them “the multi-purpose rubber transfer type molding machine (semiautomatic rubber injection molding machine) based on the frequency conversion technology” was established as National Science and Technology Ministry innovation fund project of technology type medium and small enterprises.

Features:

Clamping cylinder clamps mould first, then injection cylinder press rubber material into mould cavity uniformly. Therefore the rubber parts have precision dimension, uniform and stable performances.

It uses the original imported high pressure pump, and middle and high pressure vane pump combination, controlled by proportional pressure & flow composite valve, hydraulic system configuration is advanced, reasonable and reliable with low noise and low energy consumption.

The main moving platen raises rapidly, clamps slowly, declines rapidly, so the efficiency is improved and the mould is protected

It uses automatic in-out mould and ejector mechanism, reduces labor intensity and avoids the artificial damage to mould

The hydraulic cylinder uses patent technology of oil cylinder composite sealing device (Patent No.ZL03220060.3)which is with independent intellectual property rights, with reliable seal and long service life

The oil tank adopts the patent technology of turn board structure open tank(Patent No.ZL200620105181.5), it saves time and effort for maintenance , more human-friendly.

The electric system adopts full computer control, it is convenient for operation. It has two working modes of point moving and semi automation. Users can choose PLC control and 5.7-inch touch-control screen imported from Siemens or Mitsubishi

Preparing material is simple, fast. Production efficiency is high.

Chap researched and developed the first rubber transfer type molding machine in China in 1996,with sixteen years experience, three generations machine model, supporting with seven patent technologies.

Including most common products produced by rubber injection molding machine, it also can produce complex shape, metallic insert, high-precision, top-quality products which is difficult to form. So that performs its excellent quality and cost price merits.

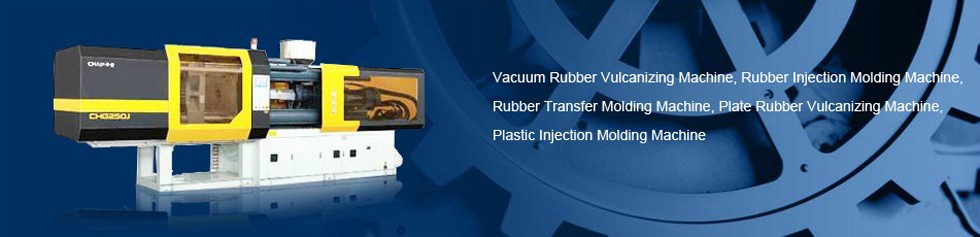

XZB series advantage

1) Clamping the mould tightly before vulcanization, then press the rubber material into mould cavities evenly, the product with little flashes, good physical performance and high qualified rate.2) Using the patent technology of our company in injection system, advanced structure design and material processing, small gap of coupling without adhering to cylinder.

3) No remain material in material cylinder, reduce waste material, convenient for material changing and mould replacing, can meet demand for small quantity production.

4) Wide application, it can produce most products without the hardness up to Shore 90 degrees, it‘s easy for preparing material and also can shorten the vulcanization time.

5) One machine carries out two program modes, are available both for Transfer molding machine and for Plate vulcanizing press.

6) Simple mould structure, reduce mould making cost.

Optional:

1. Special mould opening devices(3RT,4RT and guide-rail opening mould)

2. Material pre-heating system;

3. Frequency conversion-energy saving system.

Flow of machine motions:

Initial state→ Reposit the ejector cylinder → Load the mould → Close the mould quickly → Clamp the mould slowly, increase pressure → Put material in manually ,injection pole goes down, inject the material→Exhaust/ Vulcanize →Pushing out the mould→ Ejector cylinder works, and separate mould and product→Take out the product

Technical Parameter

|

Item Parameters |

C-XZB-D500×500/1000 |

|

Clamping force (KN) |

1000 |

|

Max System Pressure (MPa) |

23 |

|

Clamping stroke (mm) |

300 |

|

Rapid clamping speed (mm/s) |

≥50 |

|

Heating platen size (mm×mm) |

500×500 |

|

Heating Plate Spacing (mm) |

200~400 |

|

Max temperature (°C) |

250 |

|

Material Cylinder Spec(Dia-mm×Hei-mm) |

Φ80×255 |

|

Injection Stroke (mm) |

440 |

|

Injection Pressure (MPa) |

110 |

|

Ejector Stroke (mm) |

250 |

|

Max Ejector Force (kN) |

60 |

|

Motor Power (kW) |

5.5 |

|

Heating Power (kW) |

9.8 |

|

External Dimension(L×W×H)mm |

1660×2100×(2800—3000) |

|

Weight (kg) |

3600 |

|

Oil Tank Capacity (L) |

270 |

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文