- Company Name:

NINGBO CHAP MEH SANDT DEVELOPMENT CO.,LTD - Contact Person: Lydia Yang

- Tel: 86-574-83086181

15867874911 - Fax: 86-574-83086082

- Email: info@chap-china.com

- Address: Lixie village,hengxi town,Yinzhou District,Ningbo,Zhejiang,China

- WebSite: http://www.chapmachinery.com/ http://www.chap-machinery.com

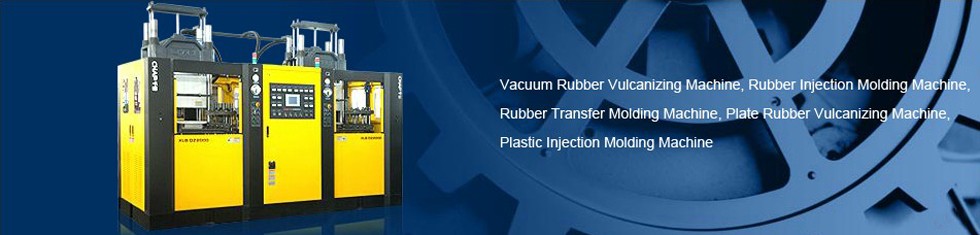

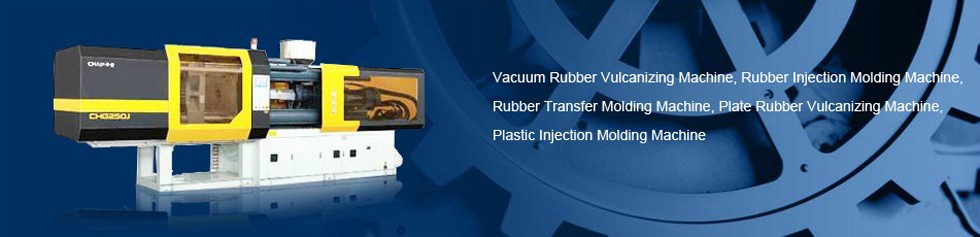

As a national high-tech enterprise, CHAP has dozens of patents, for example, “hydraulic injection molding machine with clamping structure”,the company also has national key new products, the National Science and Technology. Achievement Program, and the National Ministry of Science and Enterprise Technology Innovation Fund Projects.

Besides the traditional link-type (toggle) injection molding machines of various specifications, CHAP also has the most advanced full hydraulic two platen plastic injection molding machine, and formed a medical products, thermosetting injection molding , bi-color plastic,special machines and other system perform solutions.

What is the difference with other injection molding machine factories is that CHAP has years of research and production experience of two platen injection molding machine, the innovations used in the field of injection molding machines, to achieve industrial applications.

The full hydraulic two platen plastic injection molding machine has the advantage that conventional rod machine do not have. Not only in the technical features, more reliability and convenience in embody the value of full hydraulic two platen plastic injection molding machines. The applications of hydraulic injection molding machine is the systemic breakthrough of the application of the traditional injection molding machine. In terms of technology, hydraulic application of the two platen structure, breaks the bottlenecks in the application of traditional mechanical structure of injection molding ,which enables customers to design more targeted application of more energy—efficient injection molding products.

For meeting your increasing demand,and insuring our users own more advantages in drastic competition, we will always struggle on the road and make more contributions for our clients,employees and society.

CMG1680

Specification

DESCRIPITION

INJECTION UNIT

Screw no

A

B

C

Screw diameter

mm

42

45

50

Screw LD ratio

L/D

22

20

18

Theoretical injection capacity

cm3

343

395

488

Injection weight(PS)

g

312

359

444

Injection pressure

Mpa

177

154

125

Plasticizing capacity(PS)

g/s

16.5

18.7

22

Screw speed

rpm

0~190

CLAMPING UNIT

Clamping force

KN

1680

Moving mould distance

mm

420

Tie bar spacing

mm

460×460

Max.mould thickness

mm

500

Min.mould thickness

mm

180

Ejector stroke

mm

120

Ejector force

KN

39

Ejector bar amount

PC

5

OTHERS

Max.pump pressure

Mpa

16

Pump motor power

KW

15

Heating power

KW

9.3

External dimension(L×W×H)

m

5.03×1.4×1.84

Weight

t

4.6

Material cylinder capacity

L

25

Oil tank capacity

L

300

UNIT

CMG1680

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文