- Company Name:

NINGBO CHAP MEH SANDT DEVELOPMENT CO.,LTD - Contact Person: Lydia Yang

- Tel: 86-574-83086181

15867874911 - Fax: 86-574-83086082

- Email: info@chap-china.com

- Address: Lixie village,hengxi town,Yinzhou District,Ningbo,Zhejiang,China

- WebSite: http://www.chapmachinery.com/ http://www.chap-machinery.com

Summary:

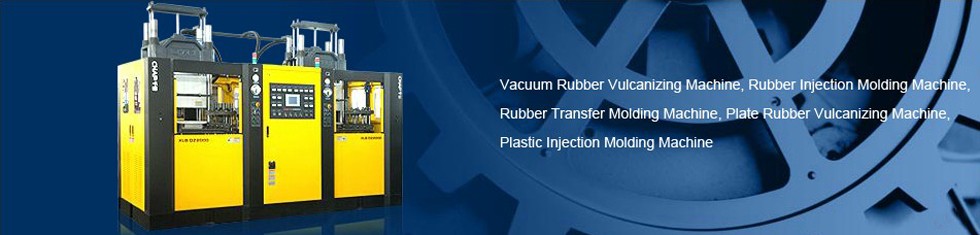

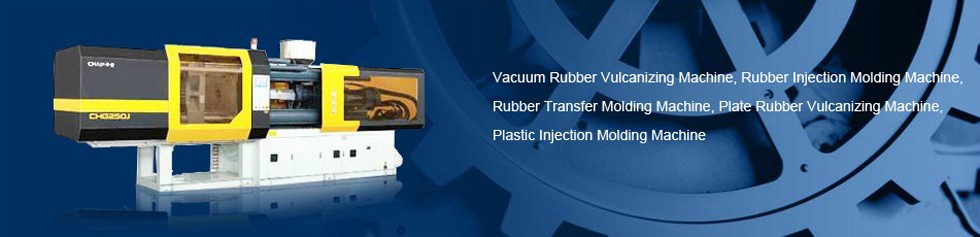

XLB series plate vulcanizing press for rubber is the main molding equipments for various of rubber molding products and non-molding products, with simple structure, high pressure, wide applicability, and high efficiency. The equipment is also suitable for molding to thermosetting plastic, bubble, resins, bakelite, sheet metal, building materials and other molding products.

Features:

The main moving platen raises rapidly, clamps slowly, declines rapidly, closing mould and exhausting can be adjusted respectively, production efficiency is improved.(except XLB/400).

Hydraulic system configuration is more reasonable and reliable. when products are vulcanizing, oil pump and motor stop working, and has automatic pressure compensation function and oil pump stands with delay,

Exhaust time, exhaust frequency, heating temperature and vulcanizing time can be seted, it is convenient for operation. There are two work modes with manual and semi automatic mode

To meet the requirements of special rubber material, there are two working mode.ordinary plate vulcanizing press; transfer mould working mode.

The hydraulic cylinder uses our own patent technology of oil cylinder composite sealing device (patent nu.ZL03220060.3), with reliable seals technology and long life

The electric system adopts full computer control, it is more convenient, accurate and reliable for operation. Users can choose PLC control and 5.7-inch touch-control screen imported from Siemens or Mitsubishi.

The oil tank adopts the patent technology of flip board structure open tank (patent nu.ZL200620105181.5), it saves time and effort for maintenance , more human-friendly.

Flow of machine motions:

Initial state →Put the material into the mould, reposit the ejector cylinder →Load the mould →Close the mould quickly→ Clamp the mould slowly, increase pressure →Exhaust→Vulcanization start →Vulcanization finish→Open mould quickly→ Pushing out the mould →Ejector cylinder works, and separate mould and product→Take out the product

Technical Parameter

|

Item Parameters |

C-XLB-D550×600/2000 |

|

Clamping force (kN) |

2000 |

|

Clamping Stroke (mm) |

300 |

|

Rapid clamping speed (mm/s) |

≥50 |

|

Heating Plate Size (mm×mm) |

550×600 |

|

Heating plate spacing (mm) |

180~480 |

|

Max Temperature (°C) |

250 |

|

Number of working layers (layers) |

1 |

|

Ejector stroke (mm) |

300 |

|

Max ejector force (kN) |

60 |

|

Motor Power (kW) |

5.5 |

|

Heating Power (kW) |

14 |

|

External Dimension(L×W×H) |

2020×2500×2100 |

|

Weight (kg) |

4500 |

|

Oil Tank Capacity (L) |

350 |

Deutsch

Deutsch Español

Español Français

Français Italiano

Italiano Português

Português 日本の

日本の 한국어

한국어 العربية

العربية български

български hrvatski

hrvatski česky

česky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικά

Ελληνικά हिन्दी

हिन्दी norsk

norsk Polski

Polski Română

Română русский

русский Svenska

Svenska 中文

中文